Breakthrough in Alkali Antimonide Photocathode Growth - Pure Metal Evaporation Enables Photon Detection and High-Brightness Electron Sources

Innovative Photocathode Materials Drive Electron Technology Revolution

Recently, Luca Cultrera and Ivan Bazarov from the Cornell Laboratory for Accelerator Based Science and Education, Cornell University, along with their collaborator Hyeri Lee, published an important paper in the Journal of Vacuum Science & Technology B, introducing an innovative method for growing alkali antimonide photocathodes. This groundbreaking research opens up new opportunities in the fields of photon detection and high-brightness electron sources.

Alkali antimonide materials have been the focus of intense interest due to their applications in single-photon detection and high-quality electron beam sources. These materials can produce electron beams with low average transverse energy when operated at low temperatures, making them well-suited for advanced techniques such as ultrafast electron diffraction.

Traditional methods for synthesizing alkali antimonides rely on the spontaneous chemical reaction between an antimony (Sb) thin film and alkali metal vapors under ultra-high vacuum conditions. However, this new research employs an innovative approach - using pure metal vapors from evaporation cells to directly grow the photocathode materials. This method enables the uniform growth of high-performance photocathodes over large areas.

PBN Crucibles Ensure Controlled Growth Process

PBN material is a type of boron nitride material created by CVD process. As a result, it close to theoretical value of density, almost perfect crystalline structure and extremely high purity. The research team choose PBN crucibles in their experiment because its high purity and compatibility with high vacuum environment and molten metal. In the experimental setup, the research team used an ultra-high vacuum (UHV) chamber maintained by an ion pump. The alkali metal source consists of four evaporation cells, each equipped with mechanical shutters and containing pure metals.

To address the challenge of the high vapor pressure of alkali metals, the geometric configuration of the evaporation cells was specially designed, with the PBN crucibles positioned at a near-vertical angle. This effectively prevents the liquid alkali metals from spilling out of the crucibles and into the vacuum chamber, ensuring the safety and controllability of the experimental process.

QSAM Inc., as a leading manufacturer of PBN materials, provides high-quality customized services to research users. Our expertise in PBN manufacturing and customization enables researchers to obtain the most suitable high-quality crucibles and parts, supporting the advancement of scientific research.

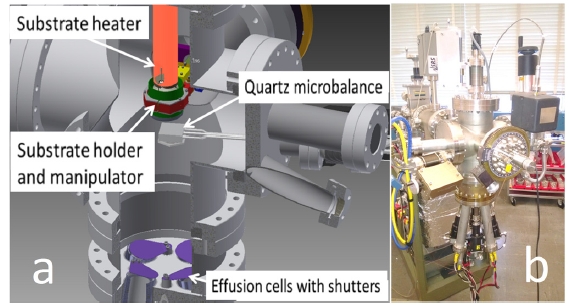

UHV growth chamber with effusion cells for evaporation of pure metals

High-Performance Photocathodes Grown by Pure Metal Evaporation

During the growth process, the research team first deposited a layer of antimony (Sb) on the substrate, and then opened the corresponding evaporation cell shutters to allow the alkali metal vapors to react with the Sb layer, forming the alkali antimonide compounds. By adjusting the temperature of the evaporation cells and the shutter opening times, they were able to precisely control the deposition rate and thickness of the materials.

This innovative pure metal evaporation growth method successfully produced Na2KSb dual-alkali and Na2KSb:Cs3Sb multi-alkali photocathodes on stainless steel and Borofloat 33 glass substrates. These photocathodes exhibited peak quantum efficiencies (QE) exceeding 20%, making them highly suitable for photon detection and next-generation electron sources.

Furthermore, by depositing additional cesium (Cs) and Sb, the research team expanded the infrared spectral sensitivity of these photocathodes (beyond 800 nm). Although the QE in this range is still lower than commercial photomultiplier tubes, this breakthrough opens up new possibilities for mid-infrared optical applications.

Prospects for Large-Area, High-Quality Photocathodes

Currently, the growth experiments are limited to samples of approximately 2-inch diameter. However, the research team suggests that by simply scaling up the growth chamber, it is possible to achieve uniform deposition on larger substrates in the future, enabling the production of high-performance photocathodes with even larger areas.

The use of PBN crucibles not only helps to control the alkali metal vapor pressure but also reduces the high-temperature evaporation of GeS2, further improving the controllability of the crystal growth process. QSAM Inc.'s expertise in PBN crucible manufacturing has provided valuable support for this groundbreaking research.

The continuous innovation in alkali antimonide photocathodes will undoubtedly spark a new wave of technological revolution in the fields of photon detection, electron beam sources, and mid-infrared optics. It is believed that the frontier applications based on this novel optoelectronic material will flourish, benefiting the advancement of technology.