Cerium (Ce) Sputtering Targets

Composition: Cerium (Ce)

Catalog No.DPME58ST

Purity:99.9%(REM)Please click ![]() for discount and other size

for discount and other size

- Product Details

Cerium (Ce) sputtering target specifications

Formula: Ce

CAS No.: 7440-45-1

Max. dia. of flat disc sputter target: 14" dia

Typical lead time of Ce sputtering target:2 weeks

Regular Dimensions and Price of Cerium (Ce) Sputtering Target

| Product Name | Reference Price | |

| 2"diax 1/8"t Cerium sputtering target | $335 | Add to Chart |

| 3"diax 1/8"t Cerium sputtering target | $391 | Add to Chart |

| 2"diax 1/8"t Ce sputtering target with In bonding to Cu bck plt | $415 | Add to Chart |

| 3"diax 1/8"t Ce sputtering target with In bonding to Cu bck plt | $526 | Add to Chart |

About Our Sputtering Target

QS Advanced Materials Inc is a professional supplier of custom manufacturered R&D consumptions. Our equipment setup are flexible to meet various demands from wide range of customers for flat disc sputter targets. We are supporting US national labs and worldwide univeristies and researching facilities with our target material and other customized product. Please check here for the list of our other Rare Earth Metals sputter targets

Sputtering Cerium

Cerium (Ce) thin-film coatings, particularly those deposited via sputtering, are utilized in various high-tech applications due to ceriums unique properties, such as its high corrosion resistance and optical properties. Cerium oxide thin films are commonly applied in optics for UV filters and anti-reflective coatings. They are also used in the electronics industry for semiconductor devices, and in energy sectors, such as in solid oxide fuel cells for their ionic conductivity and in catalytic converters due to their oxygen storage capacity.

The sputtering process of cerium involves a vacuum chamber where a cerium target is bombarded with high-energy argon ions. These ions dislodge cerium atoms from the target, which then travel through the vacuum and deposit onto a substrate, creating a thin film. Parameters like the power input to the sputtering cathode, the working pressure in the chamber, the distance between the target and the substrate, and the substrate temperature are meticulously adjusted to control the films thickness, adhesion, and crystalline structure. The sputtering of cerium films often requires precise control over the oxygen partial pressure in reactive sputtering to ensure the correct stoichiometry and properties of the resulting cerium oxide film.

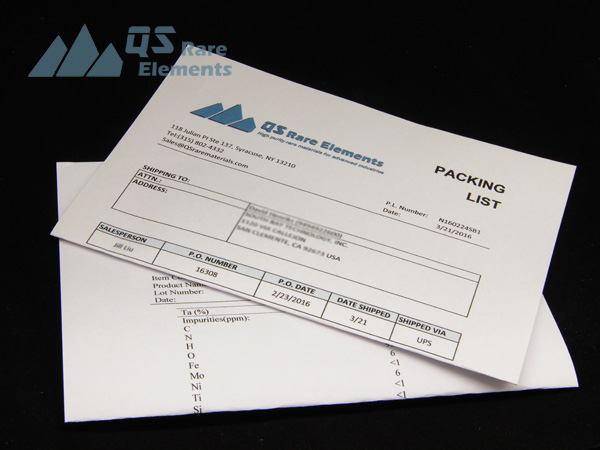

Cerium Sputtering Target Packaging

QS Advanced Materials Incs sputter targets are vacuum sealed in plastic bags for shipping. We also use heavy foam to protect it. Common documents together with the sputter targets are packing list and analytical report e.g. COA

To protect the cerium sputter target from oxygen, we usually leave a little bit oil in the package. Please check the article "Cleaning Deposition Materials Packaged in Oil" for more details about cleaning the target.

Related Product