Cobalt (Co) Sputtering Targets

Composition: Cobalt

Catalog No.DPME27ST

Purity:99.9% ~ 99.99%Please click ![]() for discount and other size

for discount and other size

- Product Details

Cobalt (Co) sputtering target specifications

Formula: Co

CAS No.: 7440-48-4

Max. dia. of flat disc sputter target: 18"

Typical lead time of Co sputtering target:2 weeks

Regular Dimensions and Price of Cobalt (Co) Sputtering Target

| Product Name | Reference Price | |

| 2"diax 1/8"t Cobalt sputtering target | $320.5 | Add to Chart |

| 3"diax 1/8"t Cobalt sputtering target | $326 | Add to Chart |

| 2"diax 1/8"t Co sputtering target with In bonding to Cu bck plt | $401 | Add to Chart |

| 3"diax 1/8"t Co sputtering target with In bonding to Cu bck plt | $461 | Add to Chart |

About Our Sputtering Target

QS Advanced Materials Inc is a professional supplier of custom manufacturered R&D consumptions. Our equipment setup are flexible to meet various demands from wide range of customers for flat disc sputter targets. At QSAM inc, we are committed to delivering superior quality targets and services for the scientific research community and high-end manufacturing industry. Our cobalt sputter targets are designed for reliability and performance, ensuring that our clients can achieve the best results in their thin film applications. Please also check here for the list of our other Single Element sputter targets

Sputtering Cobalt

Sputtering is a widely-used method in thin film deposition, employing a physical vapor deposition (PVD) process where atoms are ejected from a solid target material due to bombardment of the target by energetic particles. In the case of a cobalt sputtering target, high-purity cobalt is used as the target material. The process begins by creating a plasma in the sputtering chamber, typically with argon gas. Ions from the plasma are accelerated towards the cobalt target with sufficient energy to dislodge cobalt atoms from the target surface. As these cobalt atoms are ejected, they travel across the vacuum chamber and deposit onto a substrate, forming a thin film with the desired properties. The sputtering conditions, including the power applied to the target, vacuum level, and gas composition, are meticulously controlled to achieve the required film characteristics, such as thickness, uniformity, and crystal structure.

Cobalt (Co) thin-film coatings produced via sputtering are integral in various sectors due to cobalts magnetic properties, wear resistance, and chemical stability. These films are predominantly used in the data storage industry for magnetic recording media. They also find applications in the electronics industry for the fabrication of magnetic sensors, inductive components, and micro-electromechanical systems (MEMS).

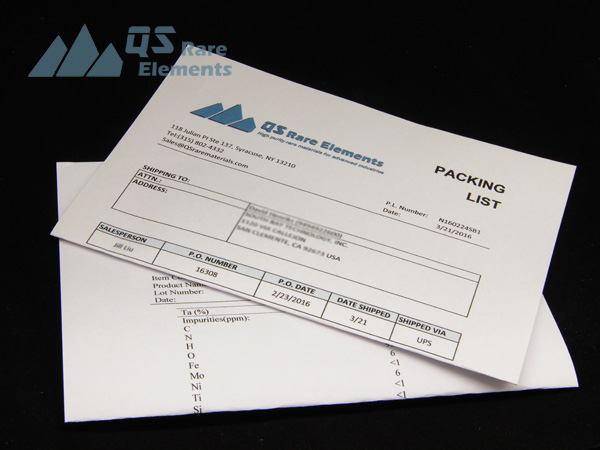

Cobalt Sputtering Target Packaging

QS Advanced Materials Incs sputter targets are vacuum sealed in plastic bags for shipping. We also use heavy foam to protect it. Common documents together with the sputter targets are packing list and analytical report e.g. COA

Related Product