Enhancing Gamma-Ray Detector Technology through Advanced Crystal Growth Modeling

Introduction

Recently, a research team led by Professor Jeffrey J. Derby from the Department of Chemical Engineering and Materials Science, University of Minnesota, published a compelling paper titled "Modeling the Crystal Growth of Cadmium Zinc Telluride: Accomplishments and Future Challenges" in the Materials Research Society's Symposium Proceedings. This paper not only provides a theoretical foundation for the advancement of detector technology but also paves the way for the development of high-performance gamma-ray detectors in the future.

The Importance of CZT Crystals

In the fabrication of gamma-ray detectors, cadmium zinc telluride (CZT) crystals play a crucial role. The high quality and large size of these crystals are key factors in ensuring detector performance. However, scientists' fundamental understanding of how CZT crystals grow and how growth conditions affect their performance is still far from adequate.

Challenges in CZT Crystal Growth

The growth process of CZT crystals is much more complex than that of traditional semiconductor crystals, facing issues such as polycrystalline grains, extended defects, second-phase particles, and poor reproducibility. These problems lead to low yields and high material costs, presenting a pressing challenge for researchers to overcome.

The Role of Computational Modeling

Professor Derby and his team argue in the paper that crystal growth computational models are a powerful tool, complementing experiments and characterization. Computational models help to close the loop between material discovery, device research, system performance, and manufacturability, thereby improving crystal quality.

Achievements of Modeling Research

The paper discusses the computational models developed and applied to understand the vertical Bridgman growth of CdTe and CZT. These models consider factors such as melt convection, heat transfer, and solute segregation, and have been successfully validated through experimental measurements.

Application of CrysMAS Software

The research team utilized the CrysMAS software for crystal growth simulation, which can predict the high-temperature heat transfer within complex crystal growth furnaces, including heat transfer, fluid flow, and phase change calculations.

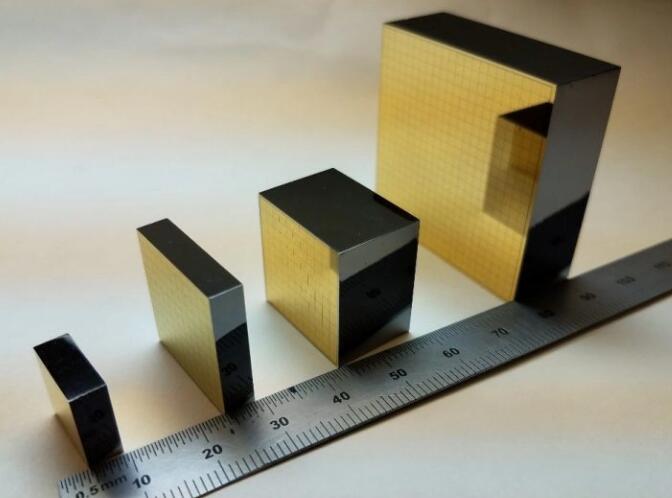

Comparison of Growth Systems

The paper presents a comparison of the conditions for growing CZT using graphite crucibles and pyrolytic boron nitride (PBN) crucibles in an electromagnetically-equipped gradient freeze (EDG) furnace. The study suggests that PBN crucibles may help suppress grain growth in the early stage.

Strategies to Solve Growth Issues

To address the problems in CZT crystal growth, the paper proposes a strategy of manipulating the thermal conditions to encourage larger gradients during the undercooling process, which may help improve the crystallinity of the crystals.

Future Directions

The paper emphasizes the need for more fundamental research on the materials science of CZT crystal growth and the development of advanced, real-time, model-based control methods to improve the quality and reduce the cost of detector-grade CZT production.

The Critical Role of PBN Crucibles in Experiments

In conducting CZT crystal growth experiments, the scientists' choice of pyrolytic boron nitride (PBN) crucibles was a crucial decision. PBN is widely used in high-temperature and high-purity material processing due to its unique physical and chemical properties. PBN crucibles have high thermal stability, excellent chemical inertness, and low thermal expansion, which allow them to maintain structural integrity and prevent reactions with the growing CZT crystals, ensuring the purity and quality of the crystals. Additionally, the high thermal conductivity of PBN crucibles helps achieve a more uniform temperature distribution and control, which is critical for crystal growth.

QSAM Inc., as a leading manufacturer of PBN crucibles in the market, provides high-quality products and services to research users. Their expertise in manufacturing and customization allows researchers to tailor the crucibles to their specific experimental needs, greatly facilitating the advancement of materials science and semiconductor research.

Conclusion

Professor Derby's paper not only reveals the complexity of CZT crystal growth but also demonstrates the immense potential of modern computational models in understanding and improving the crystal growth process. By integrating with experimental data, these models are beginning to showcase their practical value in guiding actual production.

This research was partially supported by the Department of Energy, National Nuclear Security Administration, and the computing resources were provided by the Minnesota Supercomputing Institute, which are crucial for driving the development of this frontier science.

As technology continues to progress, we have reason to believe that with the efforts of Professor Derby and his team, combined with the use of high-quality PBN crucibles and other advanced materials, the growth of CZT crystals will become more refined, greatly enhancing the performance of gamma-ray detectors and bringing more safety and security to our world.