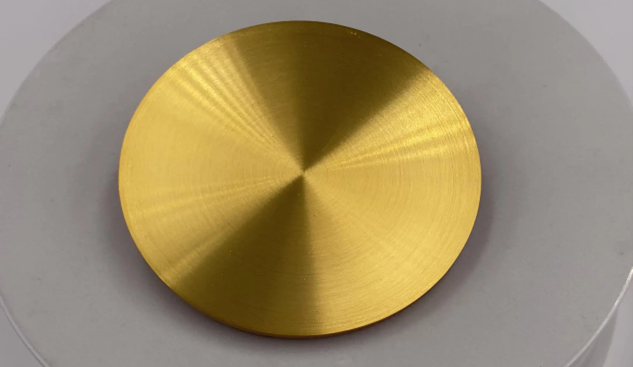

Exploring Gold Sputtering Targets

Gold's enduring preciousness stems from its unparalleled versatility and lustrous beauty. Highly malleable and ductile, gold suits endless applications from exquisite jewelry to industrial materials. Gold's excellent conductivity and resistance to corrosion also enable diverse technological uses. Coating materials with thin gold films via sputtering leverages gold’s virtues for modern innovations. Sputtering utilizes high-purity gold targets bombarded by plasma, ejecting gold atoms that deposit as uniform coatings. Target properties like purity and consistency critically impact the quality of gold films for electronics, data storage, and more. By exploring gold sputtering targets, we gain insight into how this ancient precious metal drives the latest advancements through ultra-thin coatings and nanostructures.

A Prime Overview of Gold Sputtering Targets

Gold sputtering leverages high-purity gold targets, bombarding them with energetic ions to dislodge gold atoms. These atoms sputter into a vacuum chamber, diffusing and condensing as an ultra-thin coating on a substrate. This enables precise gold deposition onto surfaces like jewelry, circuits, and medical implants. Sputtering systems control variables including pressure, voltage, and target-substrate distance to optimize uniformity. Gold molecules ejected from the eroded target condense and coalesce on the substrate as the desired thin film. By adjusting deposition parameters like temperature and sputter time, gold coatings reach specified thicknesses for enhancing optical, conductive, or protective properties.

Properties of Gold Sputtering Target

Gold sputtering targets retain the elemental properties of pure gold metal. Atomic number 79 and relative atomic mass near 197 Dalton distinguish gold's dense, malleable nature. Gold occurs naturally in ores, occasionally surfacing as shimmering flakes in rocks. Ideal targets mirror gold's purity and consistency to enable uniform coatings. Rigorous fabrication standards shape high-performing targets, while stringent purity guidelines ensure targets contain 99.99% or greater gold content. By leveraging gold's virtues like ductility, conductivity, and corrosion resistance, gold sputtering targets advance innovations through ultra-thin yet robust gold films. Target makers optimize properties like density and microstructure to guarantee precision coatings.

The Diverse Landscape of Gold Sputtering Target Uses

Gold sputtering targets enable depositing gold thin films onto specimens for scanning electron microscopy. Gold coatings prevent charging and increase signal clarity during electron beam analysis. The conducting gold layer dissipates static, facilitating clearer SEM imaging. Sputtered gold also protects delicate samples against beam damage while providing contrast. Additionally, gold films serve essential roles in electronics manufacturing by coating components with corrosion resistant, highly conductive connections. Beyond microscopy and semiconductors, gold sputtering applies ultra-thin coatings onto optical lenses, medical devices, and luxury jewelry.

Gold sputtering enables vast technological capabilities from semiconductors to optics. Targets eject gold atoms that uniformly coat surfaces by condensing as thin films with specialized properties. For electronics, sputtered gold provides conductive circuit connections and corrosion resistance. Optical components also leverage gold's reflectivity and scratch resistance. Precision gold layers additionally enhance solar panels, data storage devices, cutting tools, and biomedical implants. With excellent uniformity at nanoscale, high-purity gold targets drive continual innovations through ultra-thin coatings and emerging nanotechnologies.

Integrated Circuits

Semiconductor fabrication demands ultra-pure gold sputtering targets to enable flawless circuits. Any residual impurities could compromise component integrity, so targets undergo rigorous refinement. Strict specifications also govern physical properties like density and hardness to ensure uniform nano-scale coatings. The high costs of semiconductor targets reflect the extreme precision required. Still, high-performing gold targets drive critical innovations in computing by depositing conductive, corrosion-resistant connections onto silicon wafers during chip fabrication. Their nano-thin gold films pave the way for denser, faster, and more powerful electronics.

Display Panel Coating Target

Panel target is mostly used in making indium tin oxide (ITO) and touch screen electrodes. During the production of flat panel display panels, the glass substrate that is coated is typically subjected to multiple sputtering coatings to form indium tin oxide (ITO) glass. After this, it is coated, processed, and assembled for making touchscreen materials for LCD panels, PDP panels, and OLED panels. There are other metal targets like aluminum, molybdenum, and silicon that can also be used in this capacity.

Photovoltaics

In solar cell manufacturing, gold sputtering targets primarily coat the back electric contacts of thin-film photovoltaics. The resulting gold layer forms a conductive back electrode to collect and direct electrical current. For crystalline silicon cells, gold plays a lesser role in fabrication. But as solar technology evolves, high-purity gold targets will likely see increasing use for optimizing efficiency and electrical output through precision nano-coatings. With excellent conductivity and reflectivity, sputtered gold films fine-tune the light absorption and energy conversion within both thin-film and silicon solar panels.

Optics Sputtering Target

Gold sputtering targets enable precise optical coatings to manipulate light transmission. Dielectric and metallic thin films deposited atop optical components alter reflectivity, absorption or polarization. Diverse industries utilize these optimized optical properties, from smartphone cameras and automotive lighting to security systems, projectors and data storage drives. Whether minimizing reflection off lenses, increasing light capture in sensors, or protecting components from scratches, sputtered gold nano-layers fine-tune the performance of modern optical devices through engineered interactions with photons.

Advanced optical devices leverage gold sputtering's precision coatings:

* Aerospace sensors with enhanced light capture

* Biometric scanners necessitating scratch resistance

* Lab equipment for illuminating DNA sequencing reactions

Summary

Gold sputtering allows tailoring thin films to optimize optical properties. With strong yet malleable gold layers just atoms thick, target engineering enables groundbreaking photonics innovations across industries, from telecommunications to biomedicine. Carefully selecting target composition and deposition conditions unlocks bespoke optical enhancements.