Rare earth elements introduction --terbium (Tb)

Terbium, is a fantastic element that has caught the attention of scientists and engineers alike. It's a real game-changer, especially in the world of technology and special materials. In this article, we're going to dive into the wonderful world of terbium products and explore their applications.

Terbium in Semiconductors

Semiconductors are an essential technology in modern electronics and computing. Terbium thin films play a critical role in semiconductor manufacturing. These ultra-thin terbium coatings serve as protective layers for semiconductor devices. In doing so, the terbium films provide vital enhancements to performance and functionality. A common technique for depositing high-quality terbium thin films is physical vapor deposition (PVD) via the sputtering process.

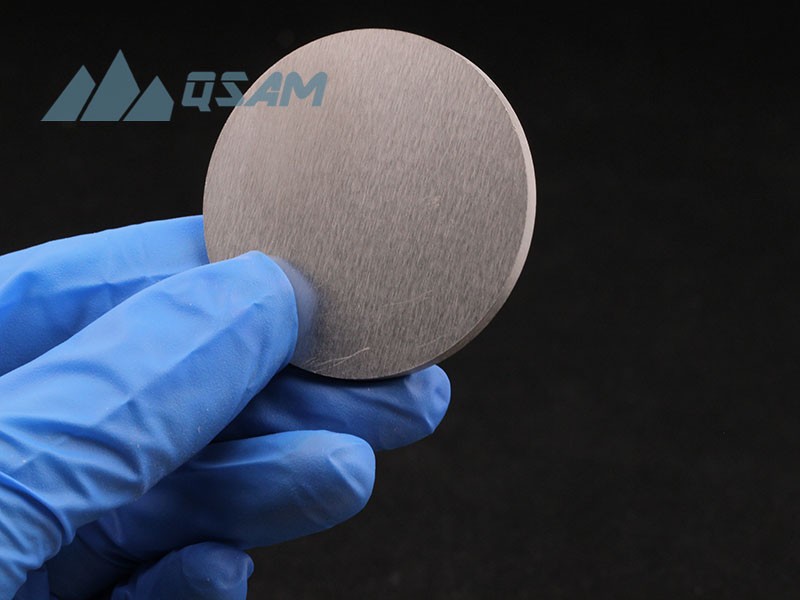

In sputtering deposition, terbium serves as the target material. It is bombarded by plasma ions which eject terbium atoms from the target. These dislodged terbium atoms then condense and coat the semiconductor wafer, forming a remarkably uniform and controlled thin film. The sputtering process enables precise control over the thickness and quality of the terbium film. This level of accuracy ensures that the terbium coating provides optimal protections and improvements to the semiconductor's capabilities.

Terbium sputter target

Terbium, the Special Functional Material

Terbium plays a critical role in the fabrication of specialized functional materials with remarkable capabilities. Of particular note are terbium-doped phosphors, which have widespread applications in advanced display technologies. By adding terbium to phosphor compounds, the resulting materials exhibit strong green photoluminescence. This luminescent property allows terbium-doped phosphors to provide the green light emission required in sophisticated display screens, including cathode ray tube (CRT) displays and modern flat-panel displays.

Additionally, terbium-doped phosphors are incorporated into security inks, counterfeit detection systems, and X-ray imaging components. The unique luminescence of terbium ions enables their use as markers in security applications and allows enhanced resolution in radiographic imaging. The versatility of terbium-doped phosphors stems from the configurable luminescent properties resulting from terbium's electronic structure.

Terbium metal

Terbium Thin Films

Terbium thin films play critical roles in semiconductor fabrication and specialized functional materials due to their unique properties and capabilities. In semiconductor manufacturing, terbium-based thin films serve as protective layers, dielectric layers, gate insulators and optical coatings that enhance performance and enable specific microelectronic functionalities. These ultra-thin terbium films are typically deposited physical vapor deposition (PVD) . In PVD process, terbium is evaporized by heat, electrical beam or ion impact. Then the terbium particles are deposited on substrate surface to create the thin film coating.

Additionally, terbium-doped hafnium oxide thin films demonstrate potential for advancing state-of-the-art MOSFET devices through improved performance. Terbium is also integral to producing specialized phosphor compounds tailored for applications in cathode ray tube (CRT) and flat-panel displays, where they provide luminescent capabilities. The configurable photoluminescence of terbium-doped phosphors also facilitates their use in security inks, counterfeiting detection, and X-ray imaging components.

In most cases, advanced sputtering PVD techniques are utilized to fabricate high-quality thin films of terbium or terbium oxide with uniform thicknesses and engineered properties. In summary, terbium thin film deposition enables specialized coatings that leverage terbium's insulating, luminescent and protective qualities to advance electronics, displays and functional materials. In this process, a piece of terbium is used as the target material in the sputtering chamber as consumption and

Conclusion

In summary, terbium demonstrates exceptional technological capabilities stemming from its unique elemental properties. In semiconductor manufacturing, terbium thin films enable protective coatings that enhance performance and provide specialized functionality through dielectric layers, gate insulators and optical coatings. Additionally, terbium is integral to producing tailored functional materials like the terbium-doped phosphors that deliver essential luminescence in display screens, security inks, counterfeiting detection and radiographic imaging components.

Whether through ultra-thin films or dopants in specialized compounds, terbium leverages its distinct properties to advance a wide range of advanced technologies. Even as a relatively scarce elemental material, terbium punches above its weight class by delivering outsized impacts in the realm of semiconductors, displays, and specialized materials. Through clever material engineering and precise deposition techniques, terbium's capabilities shine bright in the most sophisticated modern applications where specialized coatings and luminescence are crucial. This exhibits the power of rare earth elements to provide pivotal enhancements enabled by their unique atomic structures.