Large BN equipment boosts production effieciency

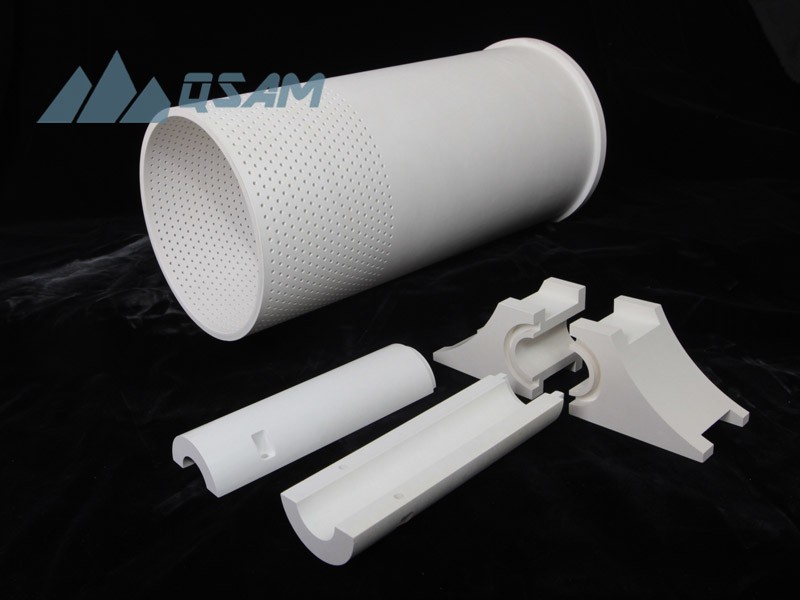

QS Advanced Materials Inc (QSAM), provider of high-tech research materials, boasts substantial production facilities that can manufacture boron nitride (BN) machinable ceramics up to 16 inches in diameter using a large hot presser.

Boron nitride ceramics have a wide range of applications, from heat sinks and electrical insulators to crucibles for high-temperature reactions. This versatility stems from the material's unique properties: high thermal conductivity, excellent electrical insulation, and remarkable resistance to heat and chemicals.

An essential aspect of BN ceramic production involves the transformation of BN blanks into finished parts through CNC machining. The size of these blanks often limits the design possibilities for BN components. However, QSAM is challenging this limitation by supplying the market with the largest available BN blanks, significantly expanding the design space for customers.

Recently, QSAM's capabilities have been put to the test in a project for a client specializing in the production of exotic metal powders. Tasked with delivering six large-scale tundishes/crucibles, QSAM utilized its comprehensive machining equipment and expertise in BN ceramics.

The larger scale and consistent performance of these BN devices garnered praise from the client. The larger size of the tundishes/crucibles allowed for increased production volumes, leading to improved overall efficiency. The client expressed high satisfaction with the outcome, appreciating the enhanced production rates achieved through the use of large-scale BN equipment.

The success of this project marks a significant milestone for QSAM and underscores the potential of large-scale BN ceramics in boosting production efficiency. Through the provision of high-quality, large-scale BN ceramics, QSAM is paving the way for innovative solutions in the realm of advanced materials, helping customers to overcome design limitations and achieve their production goals.