Nickel (Ni) Sputtering Targets

Composition: Nickel

Catalog No.DPME28ST

Purity:99.9% ~ 99.995%

Please click ![]() for discount and other size

for discount and other size

- Product Details

Nickel (Ni) sputtering target specifications

Formula: Ni

CAS No.: 7440-02-0

Max. dia. of flat disc sputter target: 18"

Typical lead time of Ni sputtering target:2 weeks

Regular Dimensions and Price of Nickel (Ni) Sputtering Target

| Product Name | Reference Price | |

| 2"diax 1/8"t Nickel sputtering target | $310.5 | Add to Chart |

| 3"diax 1/8"t Nickel sputtering target | P.O.R. | Add to Chart |

| 2"diax 1/8"t Ni sputtering target with In bonding to Cu bck plt | $391 | Add to Chart |

| 3"diax 1/8"t Ni sputtering target with In bonding to Cu bck plt | P.O.R. | Add to Chart |

About Our Sputtering Target

QSAM INC excels in the manufacturing of high-purity sputter targets, including nickel, for the USs market. Our state-of-the-art mid-frequency melting equipment allows us to cater to bespoke target dimensions and purities. We are dedicated to empowering scientific research and high-end manufacturing with our top-tier sputter targets and comprehensive service, ensuring that our clients can execute sophisticated thin film deposition with confidence and precision. Please check here for the list of our other Single Element sputter targets

Sputtering Nickel

In nickel sputtering, the specific sputtering parameters play a pivotal role in determining the quality of the nickel film. Utilizing a magnetron sputtering system, a precise voltage, often within the range of 300-500 Volts, is applied to create a plasma from the argon gas, which is maintained at pressures around 3 milli Torr. These conditions ensure efficient momentum transfer, leading to the ejection of nickel atoms from the target surface. The deposition rate and film characteristics can also be fine-tuned by adjusting the distance between the substrate and the nickel target, and by managing the power density, which is optimized around 3 Watts/cm?.

For more complex applications, co-sputtering with nickel can be employed to create specific nickel-cobalt alloy compositions, leveraging the magnetic and conductive properties of both metals. This involves simultaneous sputtering from separate nickel and cobalt targets, with precise control over the relative power levels to achieve the desired stoichiometry in the alloy film.

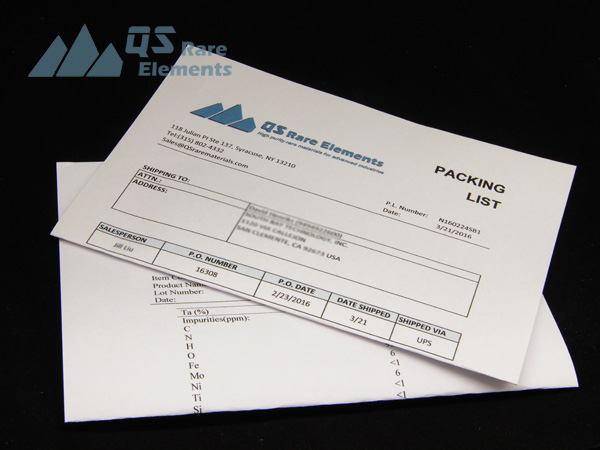

Nickel Sputtering Target Packaging

QSAMs sputter targets are vacuum sealed in plastic bags for shipping. We also use heavy foam to protect it. Common documents together with the sputter targets are packing list and analytical report e.g. COA

Related Product