PBN Crucibles Safeguard Research, Enhancing CdZnTe and CdMnTe Detector Performance

Introduction

Recently, professors Stephen U. Egarievwe and Wing Chan from Alabama A&M University, USA, along with Dr. Ki Hyun Kim from Korea University, published an important research paper in the IEEE Transactions on Nuclear Science, exploring the impact of carbon coatings and defects on the performance of CdZnTe and CdMnTe detectors. This groundbreaking research lays the foundation for improving the performance of these novel detectors, and also showcases the researchers' meticulous consideration of key materials in their experimental design.

Carbon Coatings Mitigate Crystal Defects

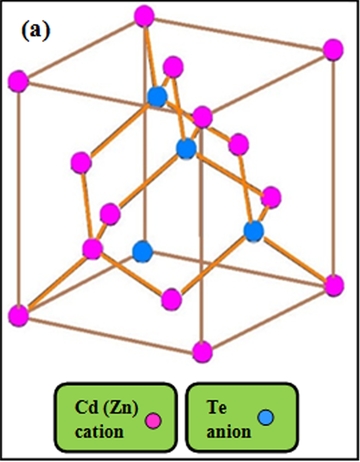

CdZnTe and CdMnTe are highly regarded as ideal detection materials due to their excellent performance in detecting X-rays and gamma-rays at room temperature. However, these materials are prone to various crystal defects, such as tellurium (Te) inclusions, dislocations, subgrain networks, and precipitates, which severely limit the performance of the detectors.

To address this challenge, the researchers utilized the Bridgman method to grow CdZnTe and CdMnTe crystals, systematically investigating the effects of carbon coating thickness and ampoule shape on crystal defects. The results showed that a thicker carbon coating (around 5μm) was more effective in reducing the dislocation density in CdZnTe crystals compared to a thinner coating (around 1μm). The shape of the ampoule had a less significant impact on the dislocation density than the carbon coating thickness. In CdMnTe crystals, using a carbon coating of around 5μm, the researchers observed very few grain boundaries and subgrain networks due to the pyrolysis of carbon.

The Critical Role of PBN Crucibles

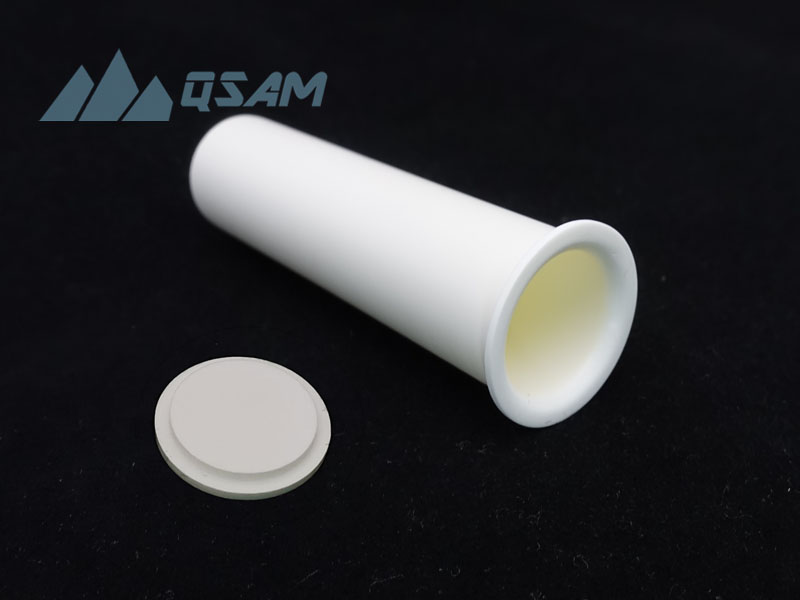

In this series of experiments, the researchers chose pyrolytic boron nitride (PBN) crucibles as the key material for growing the crystals. This choice was not accidental, as PBN crucibles play a crucial role in the growth and synthesis of semiconductor materials at high temperatures, thanks to their excellent chemical stability and low gas release rates.

Another major advantage of PBN is its purity. During the manufacture of semiconductor and optoelectronic devices, any minor impurities can lead to performance degradation. The use of PBN crucibles can significantly reduce this risk, ensuring the accuracy and reliability of experimental results. In fact, the use of PBN crucibles has become a standard quality assurance measure in the production of lasers and optoelectronic detectors.

It is worth noting that QSAM, a leading manufacturer of PBN crucibles, provides high-quality customized services for research users. They not only guarantee the high-standard quality of the crucibles, but can also tailor-make PBN crucibles to meet the specific requirements of researchers, providing strong support for the smooth progress of scientific research.

Performance Improvement Outlook

Through the systematic study of crystal defects in CdZnTe and CdMnTe, the researchers have found effective methods to suppress these defects, laying the groundwork for improving the performance of these detectors.

For CdZnTe detectors, they found that the regions with lower dislocation densities exhibited superior gamma-ray response performance. For CdMnTe crystals, the electrical resistivity can be increased by doping with indium or vanadium, reaching the performance requirements for detector-grade materials.

As these key technologies continue to be optimized, we have reason to believe that the novel detectors based on CdZnTe and CdMnTe will play important roles in medical imaging, industrial inspection, and national security, bringing more convenience and safety to human society.

Throughout this process, PBN crucibles, with their outstanding performance advantages, continue to provide a solid experimental foundation for researchers, supporting the continuous innovation of frontier technologies. As a major supplier of PBN crucibles, QSAM contributes to the scientific research endeavor, allowing scientists to focus on their research without worries.