Developing Efficient Radiation Detection Technology Using LiGaSe2 Semiconductor Material

Introduction

Recently, a collaborative study by A.C. Stowe from the Technology Development Division of the Y-12 National Security Complex and J. Woodward from the Department of Physics at Fisk University was published in the Journal of Crystal Growth. The paper, titled "Growth of LiGaSe2 Crystals for Semiconductor Radiation Detection Applications," explores the potential of LiGaSe2 as a novel radiation detection material and delves into the research on its crystal growth techniques.

LiGaSe2: A New Semiconductor Material for Radiation Detection

With the growing demand for radiation detection materials, particularly for room-temperature neutron detection, scientists have been searching for new semiconductor materials. LiGaSe2, as a lithium-containing AIBIIICVI semiconductor, has garnered attention due to its potential to incorporate a neutron-absorbing layer in the semiconductor stoichiometry. Although LiGaSe2 has been previously used for nonlinear optical applications, this study aimed to explore its potential in the field of radiation detection.

Innovative Synthesis and Growth Techniques

The research team synthesized LiGaSe2 in quartz ampoules using glassy carbon and PBN crucibles, with all steps carried out in a vacuum environment to avoid the high chemical reactivity of lithium. They used high-purity lithium metal (99.995%) and further purified it through vacuum distillation. To prevent the formation of the Ga2Li phase, the researchers employed a two-step synthesis approach, first forming LiGa and then adding selenium to form LiGaSe2. The synthesis process was optimized by precisely controlling the temperature gradient and heating rate, with a 30-hour heating at 950°C.

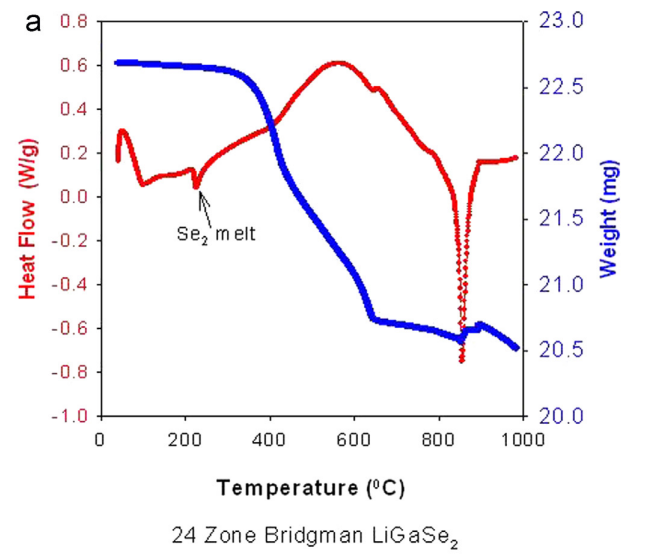

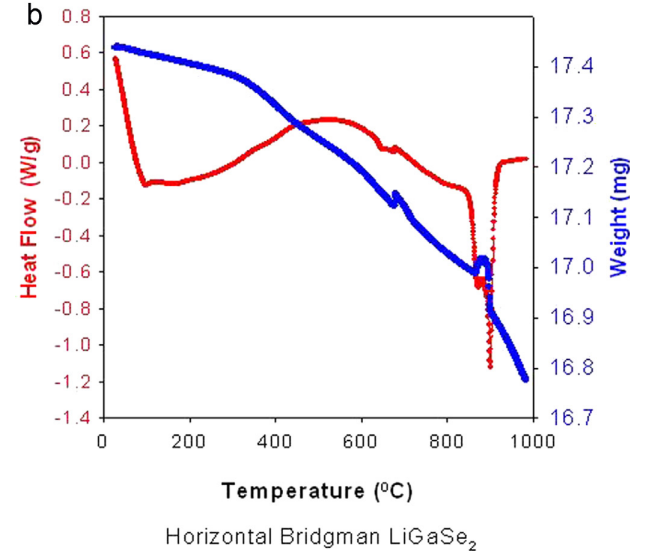

For crystal growth, the research team experimented with both vertical and horizontal Bridgman growth techniques to determine the optimal growth conditions. The vertical Bridgman growth was carried out in a 24-zone furnace, while the horizontal Bridgman growth was conducted in a three-zone furnace, with argon gas overpressure to prevent the dissociation of LGSe. The results showed that the vertical Bridgman growth produced higher-quality single crystals, while the horizontal growth resulted in the presence of secondary phases.

DSC traces of crystals grown by vertical (a) and horizontal (b) Bridgman techniques.

Li Vapor Annealing: A Key to Improving Crystal Performance

To further enhance the quality of LGSe crystals, the researchers employed a lithium vapor annealing technique. By placing additional lithium metal strips adjacent to the LGSe crystals during the annealing process, they were able to remove defects and impurities, and normalize the lithium stoichiometry throughout the crystals. The annealing process significantly improved the electrical and optical properties of the LGSe crystals, including increased resistivity and widened bandgap.

The Crucial Role of PBN Crucibles

In this research, pyrolytic boron nitride (PBN) crucibles played a critical role. PBN was chosen for its high-temperature resistance and chemical stability, which was suitable for the high-temperature and chemically active synthesis process. During the horizontal Bridgman crystal growth, PBN was used as an open crucible to contain the LGSe charge, which was then horizontally grown within a sealed quartz ampoule. In the lithium vapor annealing step, the LGSe crystals were placed in PBN crucibles, alongside additional lithium metal strips, and annealed at 600°C for 72 hours.

It is worth mentioning that QSAM Inc., as a leading manufacturer of PBN crucibles in the market, has provided high-quality services to research users. Their professional manufacturing capabilities and customization services enable researchers to obtain the most suitable high-quality crucibles for their experimental needs, further supporting the advancement of scientific research.

PBN Crucible

Future Outlook

This research demonstrates that LiGaSe2, due to its excellent electrical and optical properties, is well-suited for radiation detection applications. The vertical Bridgman growth technique has been proven to be more suitable for producing high-quality LiGaSe2 crystals. By using high-purity lithium metal and lithium vapor annealing, the researchers were able to significantly reduce defects and impurities in the crystals.

As this technology is further optimized and refined, LiGaSe2 holds great promise to become a key material for the next generation of semiconductor radiation detectors, contributing to critical areas such as national security, medical imaging, and scientific research.