Properties and Applications of Indium Tin Oxide

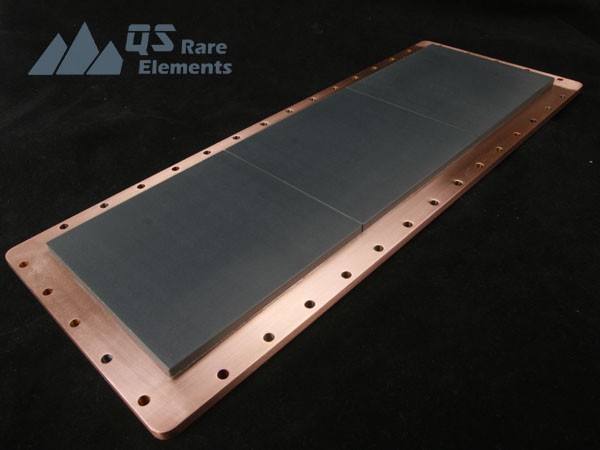

Indium tin oxide (ITO) has cemented itself as the predominant transparent conductive oxide through several advantageous properties. Possessing both electrical conductivity and optical transparency, ITO can deposit as thin uniform films via vapor deposition. This enables applying ITO coatings to products demanding both transparency and conductivity, like touchscreens and flat panel displays. Sputtering ITO targets under specific conditions allows tailoring ultra-thin films just nanometers thick. Vaporized ITO atoms condense onto substrates, forming smooth layers that transmit visible light while conducting electricity. These combined optical and electrical traits propelled ITO's rise as an essential coating for modern optoelectronics.

Before examining indium tin oxide's applications, let's detail its composition. ITO combines transparent indium oxide with conductive tin oxide, alloyed into sputtering targets. The resulting thin ITO films uniquely transmit visible light while conducting electricity. This optimal balance enabled ITO's rise as the leading transparent conductive oxide.

An Introduction to Indium Tin Oxide

Indium tin oxide (ITO) is a transparent conducting oxide that defies categorization as either an alloy or ceramic. Its composition includes indium, tin, and oxygen, but their proportions remain flexible rather than a fixed chemical formula. With higher oxygen content, ITO behaves more like a ceramic. But in oxygen-deficient sputtering targets, its properties resemble an alloy. This variability allows tuning ITO's electrical and optical characteristics through precise compositional control. By optimizing ingredients during fabrication into sputtering targets, ITO becomes a customizable thin film material essential for modern transparent electrodes.

Though not a defined compound, indium tin oxide often contains 74% indium oxide, 18% tin oxide, and 8% oxygen. This oxygen-saturated mixture combines the advantages of two metal oxides. Indium oxide provides transparency to visible light. Tin oxide lends electrical conductivity. Together in a solid solution, they create a customizable transparent semiconductor ideal for sputtering thin optoelectronic films. By tuning the ratios during target fabrication, indium tin oxide’s properties can be optimized for electrodes in flat panel displays, touch screens, and more.

Unlocking ITO's Potential: Properties of Indium Tin Oxide

Indium tin oxide (ITO) has secured broad applications as a transparent conducting oxide through two key characteristics - electrical conductivity and optical transparency. Compared to pricier alternatives, ITO's combination of affordability and performance makes it the top choice for transparent electrodes. Vapor depositing ITO into thin films only nanometers thick enables coatings on glass, plastics like PET, and various surfaces. With tunable electrical and optical properties, ITO sputtering targets allow engineering thin layers to exact specifications. This customizability catalyzed ITO's rise at the heart of touch screens, flat panels, LEDs and other cutting-edge optoelectronics.

|

Property |

Value |

Reference |

|

Mass density |

6.8 g/cm3 |

J Vac Sci Tech A 19:5(2043-7); 2001 |

|

Poisson ratio (sputtered, 10wt% SnO2) |

0.35 |

Thin Solid Films 278:1-2(12-17); 1995 |

|

fracture strength |

0.022 |

MRS Symp Proc 666 (F3.24.1 – 12); 2001 |

|

TO film stress specifically on silicon substrates |

-2.1 ~ -2.3 GPa |

Thin Solid Films 278:1-2(12-17); 1995 |

|

Index of refraction |

~1.7 @633 nm |

Appl Surf Sci 179:1-4(181-90); 2001 |

|

Electrical conductivity |

~104 S/cm |

Thin Solid Films 411:1(1-5); 2002 |

|

Biocompatibility |

no observed inhibition of cell growth; small amount of protein adsorption |

Proc IEEE/EMBS Conf on Microtechnologies in Medicine & Biology (261-4);2002 |

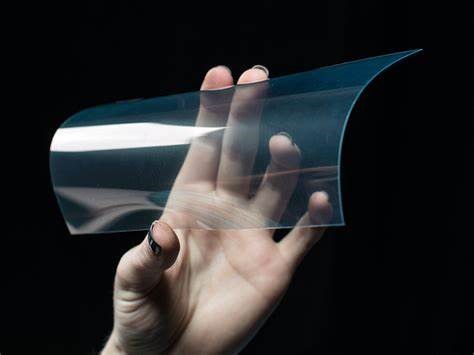

Indium tin oxide displays a high melting point from 2800-3500°F (1800-2200K), varying based on composition. The most common ITO contains roughly In4Sn. This n-type semiconductor possesses a wide bandgap close to 4 eV. ITO thin films also showcase low electrical resistivity and exceptional optical transparency exceeding 80% transmittance across visible wavelengths. These combined properties enable extensive utilization in touchscreen fabrication. By sputtering ITO targets into nano-scale films just hundreds of nanometers thick, manufacturers deposit smooth transparent layers onto displays and devices, providing both conductivity for touch sensitivity and high light transmission for crisp visuals. ITO's optimal balance of electrical and optical capabilities catalyzed its rise as an indispensable coating material for modern interactive displays.

ITO in Action: Widespread Applications of Indium Tin Oxide

Indium tin oxide (ITO) has secured status as the foremost transparent conducting oxide through widespread implementation across research and industry. What accounts for ITO’s ubiquity? Its balanced electrical conductivity and optical transparency enable diverse cutting-edge applications:

Flat-panel displays

For flat panel liquid crystal displays (LCDs), indium tin oxide (ITO) thin films still reign as the transparent electrode of choice. Device manufacturers deposit ITO layers onto substrates using sputtering or vapor deposition. This coats the interior and exterior of the LCD panel with smooth, nanoscale ITO films. The liquid crystal then resides between orientation layers, sandwiched between two conductive ITO electrodes. By transmitting over 80% of visible light, these transparent yet conductive ITO coatings prevent reflectance and enable crisp, vivid visuals. ITO's unique combination of optical clarity and electrical conductivity continues driving its implementation in cutting-edge display technologies seeking high performance transparent electrodes.

With unrivaled conductivity and transparency, indium tin oxide (ITO) reigns as the premium coating for modern display technologies. From LCD and plasma to OLED, touch screens and e-ink, ITO thin films enable both crisp visuals and touch sensitivity. When performance counts in optoelectronics, ITO is the go-to transparent electrode.

Solar cells

Indium tin oxide's high conductivity powers its implementation in both displays and solar cells, albeit with distinct roles. For photovoltaics, manufacturers exploit ITO's transmitting nature rather than conductivity. Sunlight first penetrates the glass barrier and transparent ITO electrode coating. Next, the photons interact with the active solar cell layers below, like CdTe/CdS, generating electricity. Without compromising light capture, the ITO electrode layer channels current to the external circuit. This maximizes efficiency by ensuring converted photons aren't blocked while still enabling power extraction. ITO thus unlocks the full solar-harvesting potential.

ITO Films Enable Dynamic Glass

Indium tin oxide (ITO) thin films for glass substrates are often used in making glass windows, which is an efficient strategy for conserving energy. In vehicles, ITO is utilized in windshields. Also, thin films of ITO deposited on windshields are utilized to defrost aircraft windshields. The heat that does the actual defrosting is produced by applying a voltage across the ITO film.

Lamps

Flexible electroluminescent lamps utilize indium tin oxide (ITO) coated green tapes. ITO's high conductivity and optical transparency also empower organic light-emitting diodes. As the anode, ITO thin films enable LED functionality while maximizing light emission. Additionally, ITO coatings provide conductive yet transparent EMI shielding for electronics. Whether illuminating or protecting devices, ITO brings unique capabilities to enhance performance and innovation.

Beyond displays and solar cells, indium tin oxide (ITO) thin films serve many niche applications. ITO enables infrared-reflecting auto coatings, optical filters, antireflection layers, and VCSEL laser reflectors. It also powers innovations in electrowetting, gas sensing, and sodium vapor lamps. With custom conductivity and transparency, sputtered ITO coatings deliver optimized performance across diverse cutting-edge technologies.

Advances in Transparent Conductors

Aluminum-doped zinc oxide

Alongside indium tin oxide (ITO), aluminum-doped zinc oxide (AZO) has emerged as a premier transparent conducting oxide. Manufacturers tailor the composition by adjusting aluminum and zinc ratios, yielding an Al2O3 and ZnO composite. Varying the proportions of these metal oxides enables tuning of optical and electrical properties. Like ITO, sputtered AZO thin films provide simultaneous conductivity and transparency. This drives adoption as transparent electrodes in optoelectronics like solar cells and OLEDs. Additionally, AZO serves as the electron transport layer in these devices. With performance rivaling ITO at lower materials cost, AZO films are positioned to supplement and possibly supersede ITO for certain cutting-edge applications.

Fluorine-doped tin oxide

Though less common than ITO or AZO, fluorine-doped tin oxide (FTO) sees niche use as a transparent electrode material. Manufacturers utilize FTO thin films in gas sensors, benefiting from conductivity changes upon gas exposure. FTO also facilitates photothermal conversion and serves as thermal insulation when sputtered onto building materials. However, complex synthesis compared to ITO and AZO has constrained FTO's wider adoption. With further process refinement, FTO's properties could enable expanded optoelectronic applications in the future.